Clicking the "print" button on a computer at Penn State Brandywine has taken on an entirely new meaning. Sure, students can walk to the nearest computer lab and print out their papers before class, but with the addition of a 3D printer, undergrads now have the ability to design and create three-dimensional objects.

Brandywine was the first Commonwealth Campus to receive a 3D printer, supplied by University Park. This revolutionary technology allows students who have designed three-dimensional items in a computer program to actually print out the object, which is created layer by layer out of melted plastic.

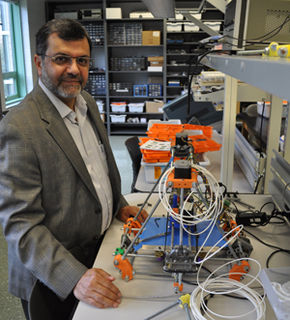

Associate Professor of Engineering Asad Azemi has big plans for the new tool and is excited that Brandywine students have access to this modern resource.

"We are actually building another printer," he explained. "We are hoping to build one, maybe two this semester. We have printed the parts that are required and now we have to buy the electronics and the motor."

Azemi said that having multiple 3D printers on campus will allow more students to have access to the technology, giving first and second year undergraduates the opportunity to work with the 3D printer.

"The more resources we provide for our students the more engaged they'll become," Azemi said. "It gives the students enjoyment because it is something they see on their computer monitor and then all of a sudden, they can actually touch that item."

Brandywine sophomore and West Grove native Tyler Storr has spent several hours working with the tool, printing components for the second 3D printer that the engineering team will build. The electrical engineering major has enjoyed being able to work with such an innovative resource.

Not only does this device support student learning, 3D printers could also have major implications on the U.S. manufacturing sector and several different medical fields.

"Having access to this resource shows designers what their 3D models look like in physical space," said Storr. "Being able to quickly put your thoughts from paper to a physical model is crucial in both product development and prototyping for real-world applications, such as the growing medical and prognostics fields."